Integrated Garment Manufacturing Services

The garment manufacturing division at Dan Liris has extensive experience in working with international apparel brands to realise their creative vision and sustainability goals through customised solutions.

Our seasoned team, state of the art equipment, research laboratory and quality control expertise are made available to each of our clients to create garment collections that bring together style, comfort, function and durability.

Sample Development

A crucial reference point to ensure that every detail is accounted for

We begin working with all of our clients by creating samples that suit all requirement in relation to look, fit and comfort. Each aspect of the garment is taken into account from fabric selection and pattern design to the cutting and sewing process as well as finishing details and accessories.

Research & Development

Access our ongoing research and development into the latest fashion trends and product performance

We are continuously undertaking our own internal research and development in relation to garment structure, fabric performance and durability which we draw on to develop the best possible products for our customers.

Laboratory

Ensuring all final products meet consumer safety standards and quality certifications

Our dedicated laboratory creates accurate colour formulations for dyeing and printing according to our customers’ specific requirements. Rigorous tests are undertaken on all dyed fabrics for colour fastness, fading and durability during the washing process.

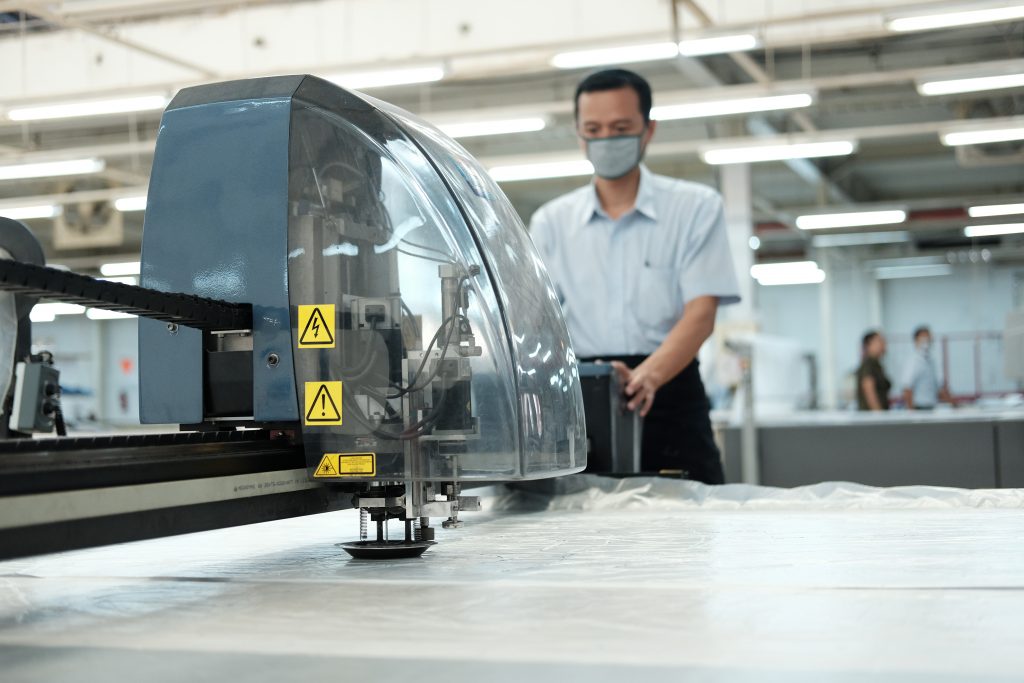

Automated Technology

Utilise our suite of automated production technology for superior results

Customers can make use of our state of the art technology including Auto-cutter, Template Machine, Pintuck Neckline, Embroidery Machine, Collarbone & Label Maker, Automatic Button Sew Indexer, Automatic Darts Seamer, Automatic Button Hole Indexer, Automatic Sleeve Placket Setter, Automatic Pocket Setter, Label Applicator, Collar & Cuff Runstitch Machine.